Damasko Watch Technology

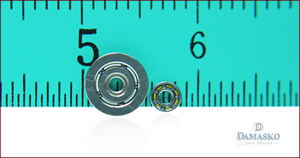

Micro Ball Bearing

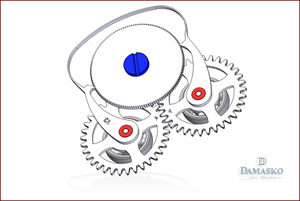

From the beginning, ease of servicing and durability were in the foreground

for the design of the Damasko calibre A35. For this reason, it was decided at

a very early stage to place the complete winding mechanism on

lubricant-free four-point micro ball bearings. The result of this is

that frictional losses are reduced to a minimum.

Also for the design the rotor fabrication for various calibres, the objective was to make the rotor bearing lubricant-free, quiet and

shock-proof, but also to keep the tilt angle as small as possible.

However, as the tilt on a normal micro ball bearing is too large due

to the geometry of its raceway, these were unsuitable for those purposes.

The so-called 4-point micro ball bearings already in use in the watch

industry, which have a divided inner race and where the bearing clearance

is adjusted by connecting or pressing on the 2nd taper ring, were also

taken into account.

However, the attempts to adjust the radial play or tilt in a defined

way turned out to be difficult due to pressing of the taper ring on

a divided four-point bearing on the inner race at an outer diameter

of 2.7mm.

A bearing with a precisely defined play had to be developed, as the

crown wheels only run on a one-sided bearing in the inner race of the

bearing and “tilting away” under stress had to be limited to a negligible

minimum. The solution was found in a new raceway geometry for Damasko micro

ball bearings. Based on this geometry, the necessary 4-point contact

was also achieved. The advantage is that the bearing consists of a single-piece

inner and outer ring. In production, these can be machined with closest

work tolerances, and afterwards the bearings are assembled using ceramic

balls with a precisely defined size or dimension. This way, for example,

radial plays of 5.10 or 15µm can be adjusted without any problems.

In addition, the resulting very small realisable radial play only permits

a so-called tilt in the µ range, which is of major importance for rotor

bearings.

Also to be mentioned is that the new bearings are manufactured from

non-corroding special steel and are fully hardened, as it is quite common

in the watch industry that the pressed-on taper ring on the inner race

on multipart four-point bearings is made of toxic copper beryllium bronze.

As the ceramic balls can be manufactured with a superfine surface structure

and neither microbonding nor frictional corrosion occurs, a lubricant

can be omitted completely. And since no lubricants can age in this way,

an unlimited lifetime is the result.